When it comes to shipping and fulfillment, the first thought that strikes my mind is a picture of a warehouse stocked with products, right? However, the main concern arises is the left-out products that linger on shelves for months or long. Here comes the cross dock logistics system, in which products stay at warehouses for a short period and are transferred to loading vehicles or delivery docks. The process works differently for every business, still cross-docking may be an excellent fit for all your supply chain operations.

Many automotive industries focus on on-time delivery and prioritize customer satisfaction. Here the cross-dock model works as a boost for decades. Let’s understand how cross dock logistics work and become the finest solution in the modern world for ecommerce businesses. You may also learn about how a 3PL service can help in a Cross dock solution implementation.

What is Cross-Docking?

Cross Docking is known as a lean supply chain model that facilitates industries with immediate or swift transfers of orders. This system transfers finished goods and handles all ecommerce industries, involving suppliers, manufacturers or retailers to customers. It includes very short-term warehousing and cross dock logistics precisely.

Its speedy kitting and assembly services and lower shipping costs by positioning inventory closer to the delivery space make it the finest choice.

When is Cross-docking Beneficial?

Cross-docking services resolve the challenges of warehousing in logistics and are useful as a leaner supply chain. For start-ups or complex business structures, it works as a boost to accelerate their order fulfillment process. Not only does it reduce costs, but it also speeds up the delivery process to allow products to reach hubs, customers, or destinations on time.

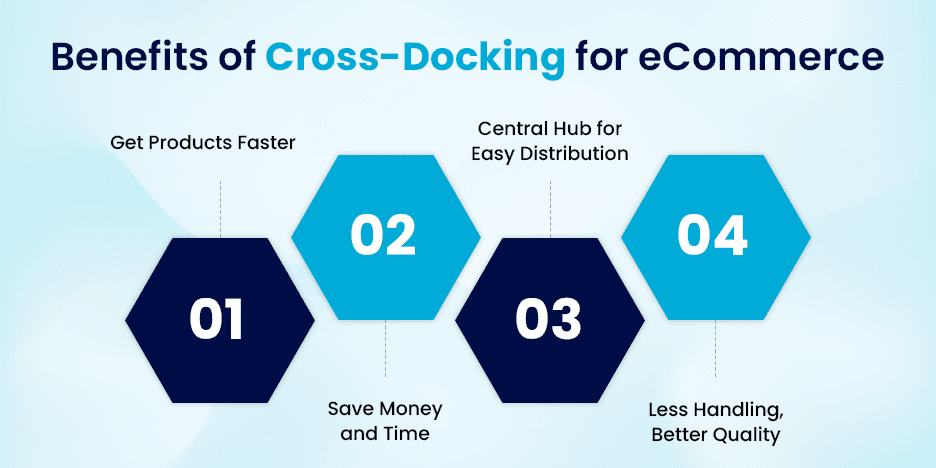

Head- Benefits of Cross-docking for eCommerce Setups

Get Products Faster:

- Cross-docking speeds up shipping and receiving. Instead of storing goods, they move quickly from incoming to outgoing trucks. This means products reach customers faster.

- Receiving is easier because you just count what comes in and goes out, skipping complex warehouse scans.

Save Money and Time:

- Cross-docking cuts costs by reducing storage and handling. You don’t need a big warehouse, saving on expenses.

- It simplifies inventory tracking, saving time and labour.

- It supports faster product replacement.

Central Hub for Easy Distribution:

- A cross-docking warehouse acts as a central sorting point. Products are organized and sent to different carriers based on where they’re going.

- It’s perfect for businesses sending large shipments to other industries or users without needing long-term storage.

Less Handling, Better Quality:

- Cross-docking reduces the number of times products are handled, minimizing damage and keeping them in good condition.

- This is especially important for perishable items like food and drinks or products with short shelf lives like makeup and medicine.

- Less handling also lessens the chance of product damage.

Who Can Get an Advantage From Cross-Docking?

Cross-dock logistics is a common term used for importers and exporters with stable, consistent demand and high inventory turnover. Except that businesses can use this process for their unique supply chain strategy and requirements. Here are the types of businesses that can take advantage of the cross-dock model.

Companies Offering Time-Sensitive Products

If your company sells important, edible, perishable, high-demand products that can easily spoil, have a short shelf-life, then opt for cross-dock logistics. Cross-docking services not only diminish the need for a supplier to store goods before online order placement, but also reduce the delivery time. The process involves the direct transportation and delivery of bulk products from the production house to the transportation dock, and then to the user. It minimizes the risk of crossing expiry dates and increases the longer sale window options for retailers.

Companies With Multiple Suppliers

Moving the goods directly from one destination to another, bypassing full storage makes the work easier. Especially, when the goods coming from multiple regions or from different distribution centers. This method makes the process easier, from receiving to ship loading from different vendors with minimum cost.

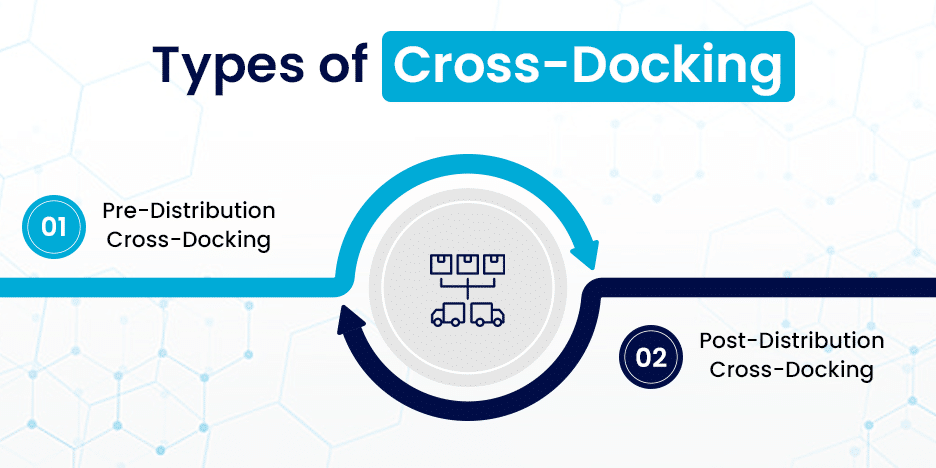

Types of Cross-Docking

Pre-Distribution Cross-Docking

In pre-distribution cross-docking, goods are unloaded, sorted, and repackaged based on pre-set distribution instructions before they leave the facility. If warehouse staff already know the end customer before the supplier ships the goods, they can immediately process the shipment upon arrival. This ensures minimal storage time at the cross-docking warehouse. This method is ideal for retailers that operate their own warehouses and have direct oversight of customer demand and supplier relations.Post-Distribution Cross-Docking

With post-distribution cross-docking, products are warehoused at the facility on a temporary basis until demand is measured and customer locations are verified. While this type of process takes marginally longer in terms of storage, it enables distributors and retailers to make strategic inventory decisions based on existing stock levels and demand forecasts.Selecting the right 3PL provider requires careful evaluation. Here are key factors to consider:

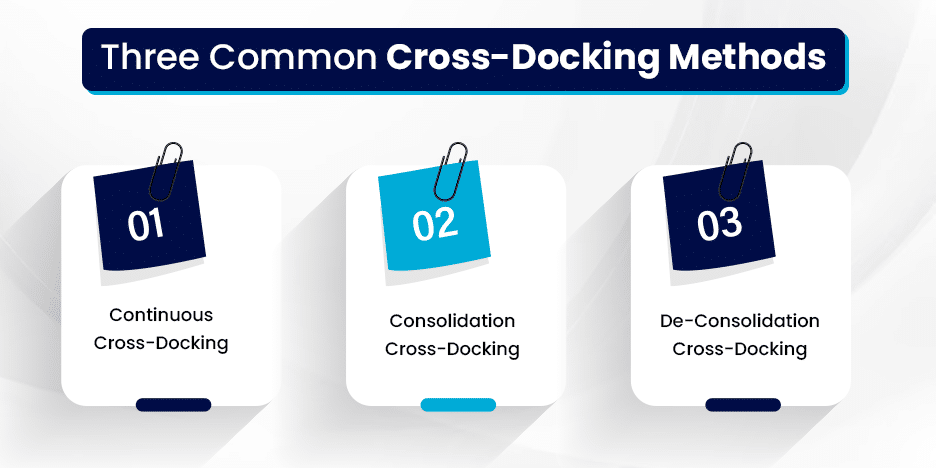

Three Common Cross-Docking Methods

The correct cross-docking strategy is based on your business model, the products you sell, and customer demand. The three most popular strategies are listed below:

- Continuous Cross-Docking

In continuous cross-docking, goods flow continuously through the facility from inbound to outbound shipments with very little waiting time. This approach provides a consistent, unbroken stream of products, minimizing waiting times even if inbound and outbound trucks arrive at varying times.

- Consolidation Cross-Docking

Consolidation cross-docking is the merging of several smaller shipments into one big load before it is shipped. This optimizes logistics through lower shipping cost since shipping parcels individually separately would be inefficient in most cases. Although products have to be temporarily staged at the warehouse to be assembled into a full truckload, they are not warehoused with other stock.

- De-Consolidation Cross-Docking

De-consolidation is the reverse of consolidation cross-docking. Rather than consolidating shipments, large shipments are disassembled into smaller, manageable lots for faster distribution. The technique is frequently applied in direct-to-consumer fulfillment to enable faster delivery to individual consumers.

By selecting the appropriate cross-dock logistics and kitting technique, companies can enhance efficiency, minimize storage expenses, and increase customer satisfaction.

Final Remark: Trust PPFD for your entire fulfillment logistics

Now, you may know a lot of things about cross dock logistics. So, it’s high time to maximize your fulfillment operation with the advanced features of cross-docking and lighten your shoulders’ burden. PPFD, a trusted 3PL fulfillment service provider, helps you implement automation in real time.

So, join our logistic network and use our premium fulfillment and cross-docking services to perform as the best brand in the industry. Plus, this way you can serve the end customer and businesses.

Share :