Let’s assume, you’re a budding fashion designer, selling your unique clothing line online. You’re excited about the growing demand, but the thought of managing inventory and shipping orders yourself is overwhelming. That’s where pick and pack services come in!

You could partner with a fulfillment center. The center will store your dresses, shirts, and accessories in its warehouse. When a customer places an order on your website, the fulfillment center’s system will pick the right items, carefully fold or hang them, and pack them securely. The center will then ship the order directly to the customer.

This way, you can focus on designing new collections, marketing your brand, and growing your business. The fulfillment center handles the tedious tasks of storage, picking, packing, and shipping, ensuring your customers receive their orders on time and in perfect condition.

If a business decides against using pick-and-pack services and handles fulfillment entirely in-house, it could face several challenges that impact efficiency, cost, and customer satisfaction. Without the streamlined processes that fulfillment services provide, in-house teams might struggle to keep up with demand, especially during busy seasons. Delays, errors, and limited scalability can quickly become significant obstacles, not only adding to operational costs but also potentially diminishing customer loyalty. Here, we’ll explore the key challenges that can arise when relying solely on in-house fulfillment.

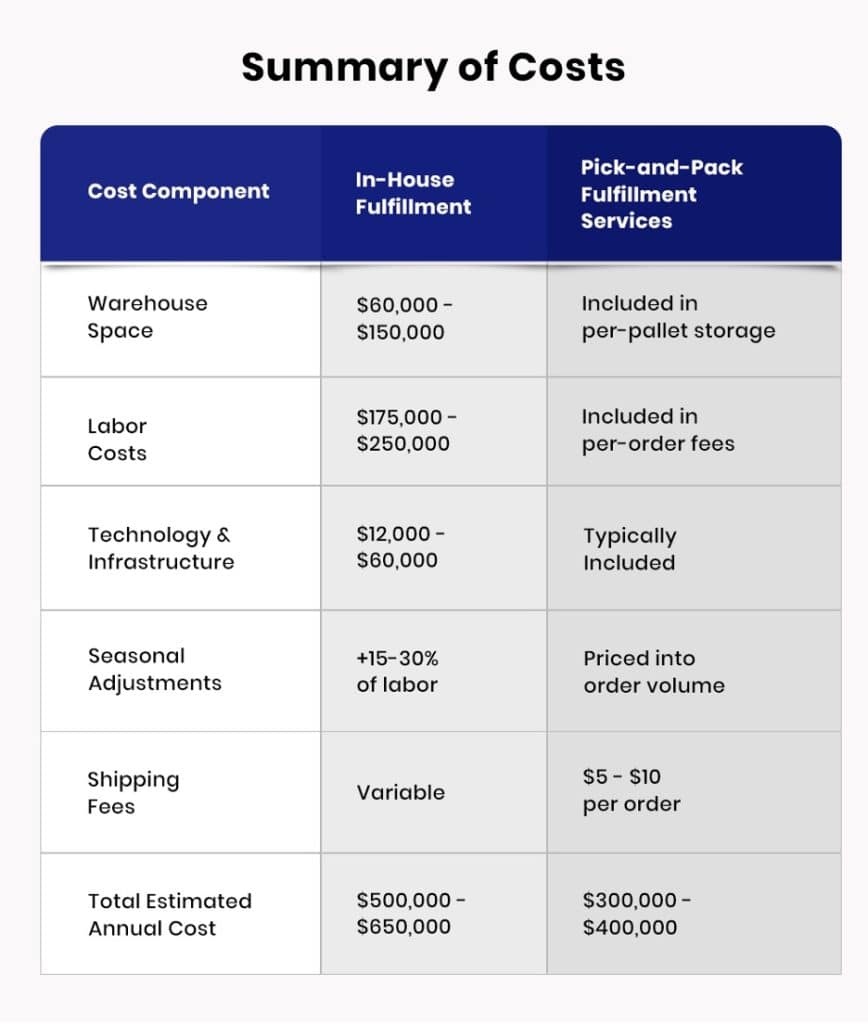

Handling order fulfillment in-house can get pricey. For starters, renting warehouse space in cities like Toronto or Vancouver isn’t cheap—especially if you need climate control for your products. Then there’s the cost of building a skilled Pick & Pack Warehousing team, which means recruiting, hiring, and training employees.

During peak seasons, these costs can skyrocket due to higher demand for labour. On top of that, managing the flow of inventory efficiently often requires advanced tech, like warehouse management systems and barcode scanning tools. These upgrades, while useful, add to the financial load, making in-house fulfillment a significant investment.

Imagine slashing your operational costs by 20% to 40%. That’s the typical reduction businesses see when they switch to a fulfillment center. Think about your current expenses—now picture paying up to 40% less. Moving to a fulfillment center isn’t just about outsourcing; it’s about reinvesting that savings right back into your business growth.

Manual order fulfillment can really slow things down. When every step—like picking items, packing them up, and creating shipping labels—is done by hand, it takes a lot longer. Plus, the more manual the process, the more likely mistakes can happen, which can delay orders even further.

If packing isn’t done efficiently, not only does it slow down shipping, but it can also lead to higher costs for packaging materials.

Altogether, relying heavily on manual work can make fulfillment slower and more expensive than automated alternatives.

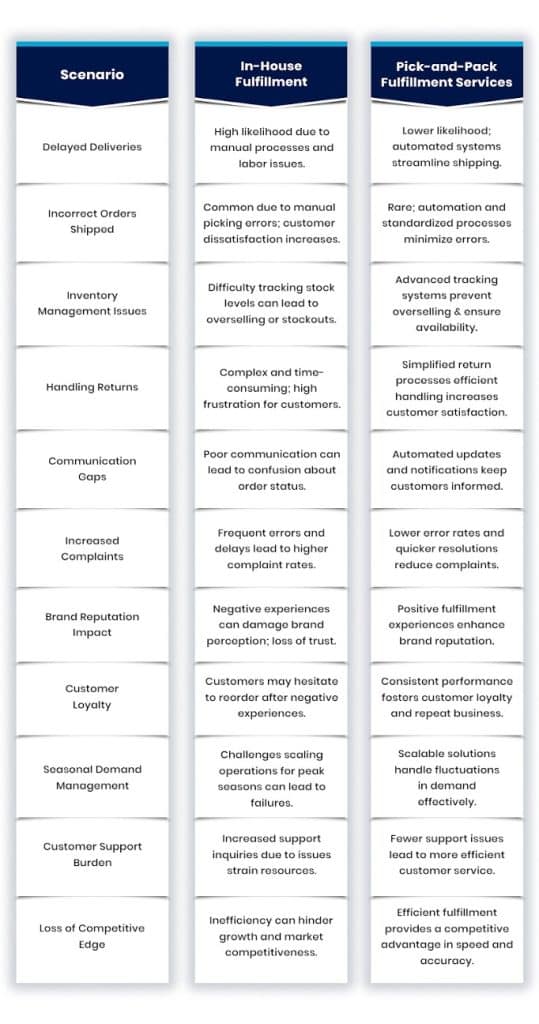

Inefficient fulfillment processes can take a real toll on customer satisfaction.

When deliveries are delayed or orders are inaccurate, it can lead to frustration, especially during high-stakes shopping seasons like Black Friday and Cyber Monday.

If items arrive late or the wrong products are shipped, customers are more likely to feel let down and may hesitate to order again. And when fulfillment errors happen too often, it can harm the brand’s reputation and result in more complaints, making it harder to maintain customer trust and loyalty.

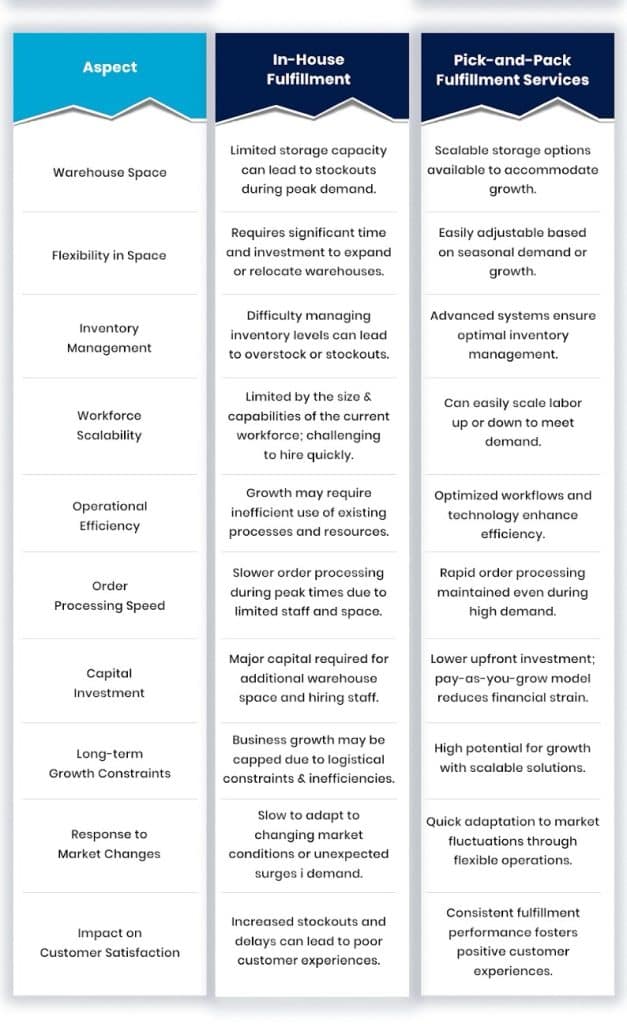

Handling fulfillment in-house can make it hard for a business to scale smoothly. If a warehouse is smaller, it may struggle to store enough stock for peak times, leading to stockouts and missed sales opportunities.

On top of that, a limited workforce can slow down order processing and shipping, especially when demand surges.

So, as the business grows, these space and staffing constraints can make it tough to keep up with increasing order volumes, putting a cap on how much the company can expand without major investments.

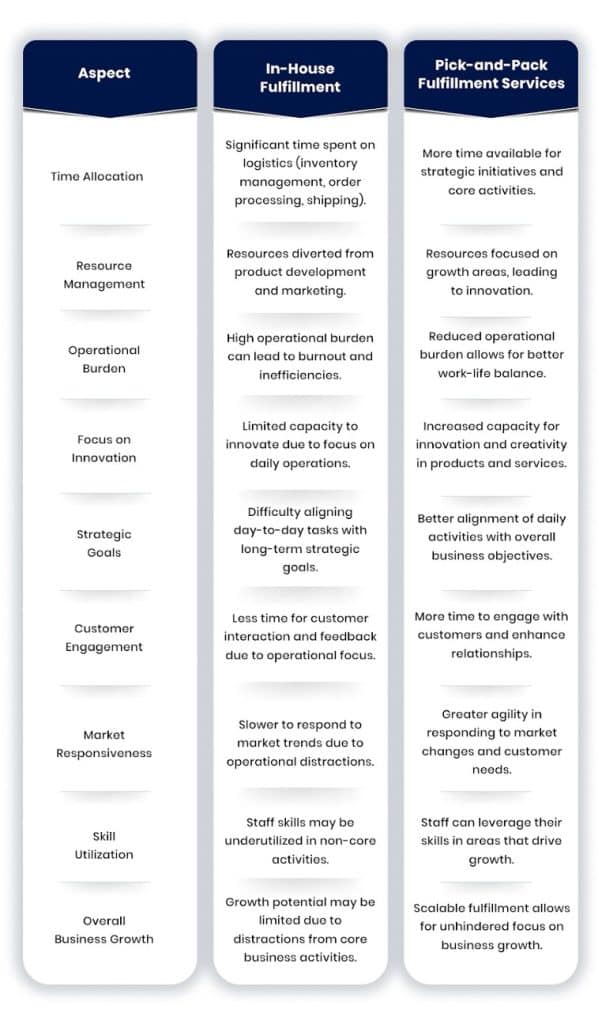

Managing fulfillment in-house often means valuable time and resources get pulled away from what truly drives business growth.

Instead of focusing on product development, marketing, or customer service, business owners can get bogged down by the daily demands of inventory management, order processing, and shipping. This focus on logistics can limit their capacity to innovate and expand the business.

Over time, all the effort spent on operational tasks can dilute attention from core goals and make it harder to push the business forward.

Imagine you’re a small business owner selling handmade jewellery online. Every time you get an order, you have to pause your creative work, gather the items, pack them carefully, print shipping labels, and take them to the post office. This can be time-consuming and take away from your core business.

With a fulfillment service, you simply send your inventory to their warehouse. When an order comes in, they handle the entire process: picking the right items, packing them securely, and shipping them directly to the customer. This frees up your time to focus on designing new pieces, marketing your business, or spending time with your family.

Fulfillment centres are designed for efficiency. They have advanced technology and experienced staff to optimize every step of the process. For instance, they might use barcode scanners to quickly locate items in their warehouse, or automated packing machines to speed up the packaging process.

Let’s say a customer orders a book and a t-shirt. Instead of manually searching for each item, a fulfillment centre worker can scan the barcode on the order and the system will guide them to the correct shelf location. This streamlined approach significantly reduces the time it takes to process each order.

Human error is inevitable. When you’re manually picking and packing orders, there’s always a risk of mistakes, such as picking the wrong item or sending the wrong quantity.

Fulfillment centres have quality control measures in place to minimize errors. They might use double-checking systems, where multiple workers verify the contents of each package. They may also implement barcode scanning technology to ensure accuracy throughout the process. This helps to avoid costly mistakes like sending the wrong item or missing a part of an order.

Fast shipping and accurate orders are key to customer satisfaction. When customers receive their orders quickly and correctly, they’re more likely to be happy and return to your store for future purchases.

Fulfillment centres can help you achieve faster shipping times by strategically locating their warehouses closer to major shipping hubs. They can also use advanced shipping software to optimize shipping routes and reduce transit times. Additionally, by minimizing errors, you can avoid the frustration and inconvenience caused by incorrect or incomplete orders.

As your online business grows, you’ll need to handle a larger volume of orders. This can be challenging if you’re still relying on manual processes. Expanding your own warehouse and hiring more staff can be expensive and time-consuming.

A fulfillment centre can help you scale your business without breaking the bank. They can handle increased order volume by adding more staff or using automated technology. This allows you to grow your business without the need for significant upfront investment.

In a nutshell, using pick and pack fulfillment services is like having a behind-the-scenes team that keeps your business running smoothly without the hassle. Instead of getting bogged down with inventory, packing, and shipping, you get to focus on the fun stuff—like designing new products or connecting with customers! These services handle everything from picking and packing to delivering orders accurately and quickly, keeping your customers happy and saving you from unnecessary stress.

Plus, as your business grows, they can scale right along with you—no need for big, costly expansions on your end. With a fulfillment partner, you’re set up for smoother operations, happy customers, and more time to do what you love. Sounds like a win-win, right?

Share :

For all your fulfillment, logistics and storage needs!

Copyright © 2024 PPFD Ltd.