Warehousing in logistics is a must in modern times for businesses to manage their overall functionality and maintain customers —-. It generally refers to the process that includes storing valuable goods and materials in a stable facility and supporting the smooth flow of the supply chain. This management ensures the whole process stays seamless, from efficient inventory management to order fulfillment. Let’s understand warehousing logistics in detail and how it benefits overall business.

Logistics Warehouses allow new setups or flourishing businesses to manage various activities and operations of the warehouse efficiently with smooth coordination with professionals. The whole process covers multiple tasks, including storing, receiving, organizing, and distributing goods within the facility. The main focus behind this is to optimize the entire process effectively for accurate inventory management and order fulfillment, saving time and cost while operating everything. The use of up-to-date and latest technology, such as 3PL fulfillment services, to streamline every ecommerce fulfillment operation and maximize productivity. Besides, every company requires effective automotive warehousing and fulfillment logistics solutions to meet customer demands, lower costs, and keep business competitive.

There are a few challenges that should be addressed by businesses to optimize warehouse service and ensure a smooth logistics process.

Space Constraints: If you’re running an eCommerce business, the primary concern in logistics is limited warehouse space. As businesses expand, the need for storage also increases. In this stage, finding sufficient space becomes difficult. Proper planning is a must to prepare a storage system and use it wisely to overcome this challenge.

Labour Management: Another challenge in logistics warehouses is to manage the workforce appropriately. For that, you need to hire trained and skilled personnel who can handle complex and advanced machinery operations. Not yet; you may also have to maintain good management with a safe working environment, productivity tracking, and labour scheduling for effective outcomes.

Inventory Accuracy: Maintaining accurate inventory records is crucial to righteous warehouse logistics management. Challenges must come, like inaccurate data entry or stock discrepancies, and more, which can directly enhance order fulfillment errors and customer bounce rates. However, if you implement an inventory management system, you can experience accuracy in conducting regular cycles and maintaining accuracy.

Seasonal Demand Variations: Seasonal fluctuations may impact many industries and their demand in the market. It can create chaos in the warehouse activity as it is not easy to manage sudden surges in orders. The challenging part during peak seasons is managing and fulfilling inventor requirements. For this, you require flexible staffing, efficient space and warehouse logistics to make an order fulfilment process smooth, but it is truly challenging to manage all this adequately.

Technology Integration: In warehouse logistics, the integration of technology can also be a challenging task for older and legacy systems. From implementing a warehouse management system to handling automated equipment and other advanced technology, all require careful planning, training, and compatible management.

Warehouse logistics comes with several benefits that contribute to the smooth functioning of overall management, including inventory and supply chains. Let’s have a look at its benefits, which include:

1- Increase In Order Fulfillment: The best part of having warehouse logistics, it can fulfil customer orders on time and boost loyalty. But how? These facilities allow the whole process, from pick-pack to shipping and delivery, to work efficiently and faster. This will, in return, enhance customer’s trust in you with timely order fulfillment solutions.

2- Improved Inventory Management: Worried about inventory management? So, relax, warehouse logistics provides a dedicated space for strong goods and enables businesses to manage their inventory efficiently. Not only does it offer you space, but it also organizes your work and stock with regular updates and tracking. When all the stages of order fulfilment are managed accurately, it improves and enhances customer satisfaction.

3 – Cost-Saver Solution: Warehouse logistics manage your everyday tasks of order fulfillment and save your costs. When you have inventory in a centralized location, there are several advantages, such as optimizing transportation costs and negotiating better pricing and suppliers. Additionally, it decreases the risk of stockouts or overstocking. Businesses can save costs of storage and holding add-on expenses.

4 – Value-Added Services: Some of the services, such as product labelling, assembly, kitting, and customization, all come under value-added services. Warehouse logistics often include these solutions to add value to the supply chain and attract an audience. It will enhance customer satisfaction and create opportunities for upselling with add-on offerings to customers.

5 – Enhanced Efficiency: Using advanced technology, warehouse logistics can help businesses streamline operations. The techies like warehouse management systems and other automated equipment improve the overall efficiency of order processing and fulfillment. From receiving orders, and storing to picking, everything goes efficiently using automated equipment. It reduces manual errors and improves productivity and order processing.

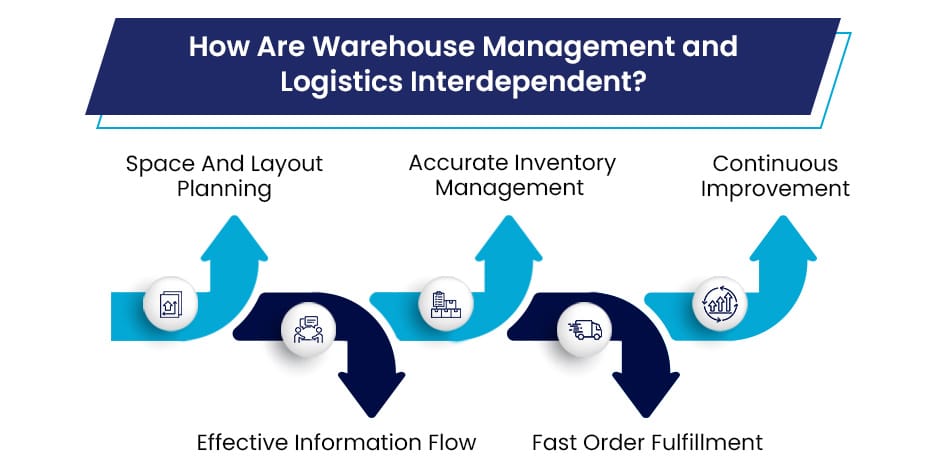

Warehouse management and logistics are closely linked with each other in the supply chain. Here are a few points to highlight their interdependence:

1- Space And Layout Planning – It is crucial to optimize space utilization within the warehouse properly; management is necessary. If the space planning is done efficiently, it ensures that the facility can accommodate inventory and run smooth logistics operations. Besides, the warehouse management team works closely with logistics professionals to understand the storage requirements precisely. The storage requirements are often different for every business, whether it is about products, planning layouts, or optimizing the flow of goods in the warehouse. The collaboration of both warehouse and logistics ensures a fluent process.

2- Effective Information Flow – Warehouse management and logistics carry an effective flow of information to effortless operations. Before planning transportation, the logistics team requires real-time inventory data that is provided by the Warehouse management system (WMS), including order management and optimizing routes. Contrarily, the logistics team helps warehouse managers by providing information about shipment schedules, transportation requirements, and delivery expectations. This exchange of information correctly ensures sync and coordination between logistics and warehouse.

3- Accurate Inventory Management – Logistics and warehouse management work together for inventory management. The warehouse manager handles the storage organization and tracking of inventory. They closely work with logistics professionals to ensure accuracy at every stage, from inventory to handling storage conditions properly. Logistics teams need the complete assistance of the warehouse team to fulfill every task of transportation, order fulfillment and supply chain activities.

Logistics and Warehouse management work together to complete customer orders appropriately. The first stage begins with the logistics team transporting goods from suppliers to the warehouse, and then the management ensures the timely fulfillment solutions, and shipping of products. To run all the processes smoothly, effective coordination and communication between warehouse and logistics teams is necessary. This way, businesses can easily fulfil customer’s requirements on time and precisely, reducing complaints.

5- Continuous Improvement – Both are interdependent and work together to identify and improve areas while optimizing the right process. When warehouse and logistics management collaborate together to analyze data and implement strategies, it’s more worthwhile. Both work together to enhance efficiency and reduce costs. Their coordination improves overall supply chain performance.

Now, you may know about the crucial role of logistics warehousing to manage the supply chain process efficiently. Well, its benefits are truly impressive, from inventory management to risk mitigation. Their coordination works well to remove supply chain complexities and faces hurdles to manage demand variations and cost. Businesses can leverage the benefits by using their warehouse logistics facilities and staying competitive in the market. PPFD is here to help you with your queries and planning for warehouse logistic management. You can talk to your experts for more specific details on your business!

Share :

For all your fulfillment, logistics and storage needs!

Copyright © 2024 PPFD Ltd.